| Rotor body and parts |

Home > Products > Rotor body and parts |

|

| |

|

|

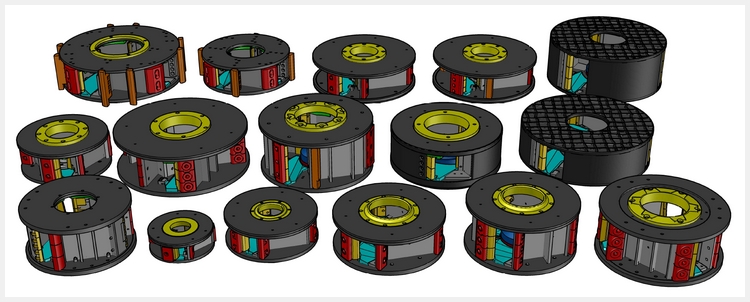

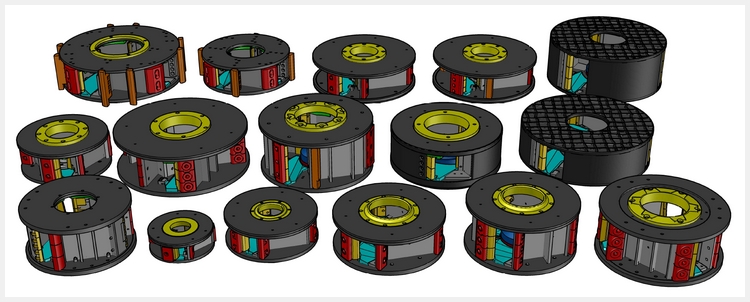

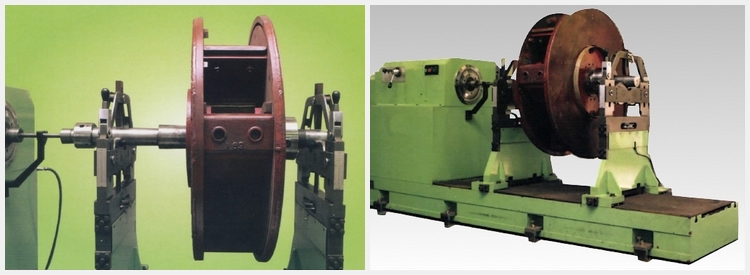

With more than 20 years of experience, we build and repair rotor bodies for almost all VSI models used in Korea, and we have always stocked rotor parts.

If there is a problem with the rotor you are currently using and you need to improve it or if you have any special needs, we will modify it after consultation with an expert.

|

| |

|

|

|

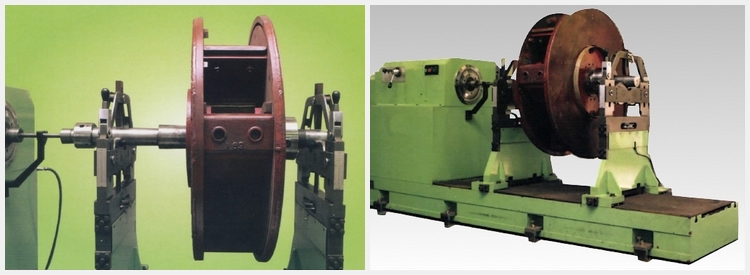

Once built or repaired, the rotor is delivered after balancing with a maximum tolerance of 30 grams using a computer balancing machine.

|

| |

|

|

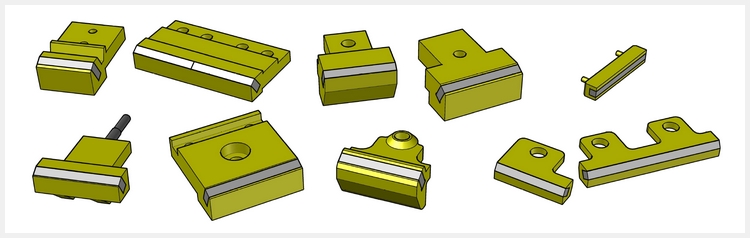

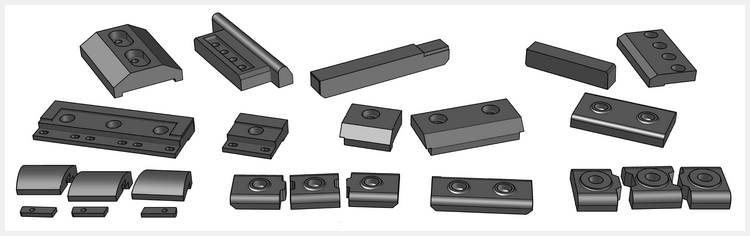

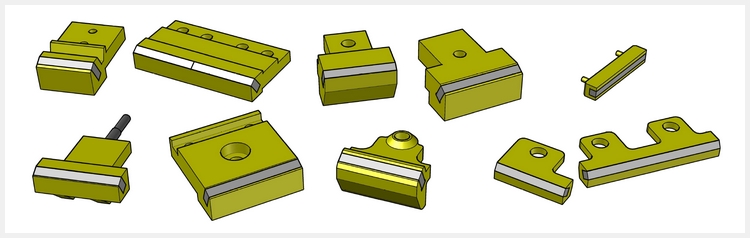

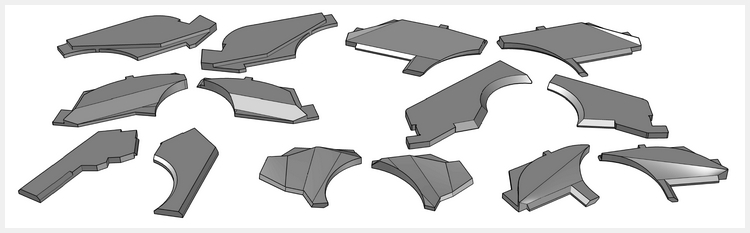

Rotor tip (Tungten carbide blade, Tip plate) / Backup tip

The rotor tip protects the area where aggregate sweeps and passes from the exit of the rotor.

Depending on the model, it may be called a tungsten carbide blade or tip plate, and tungsten carbide alloys are attached to areas with severe wear.

The backup tip provides secondary protection to prevent damage to the body even if the worn rotor tip is not replaced in time.

|

| |

|

|

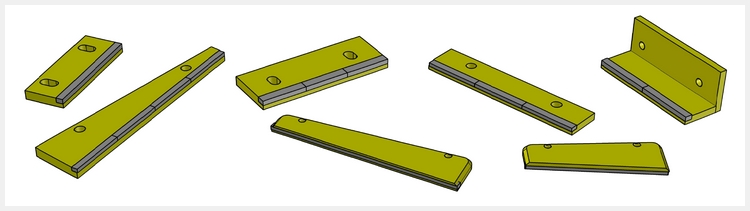

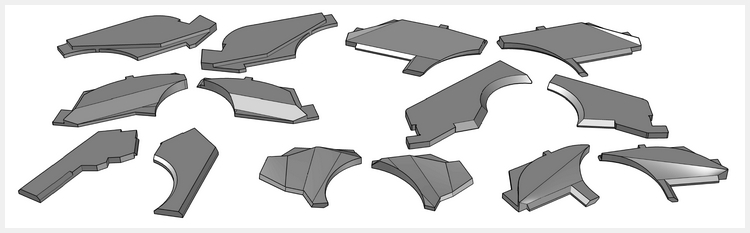

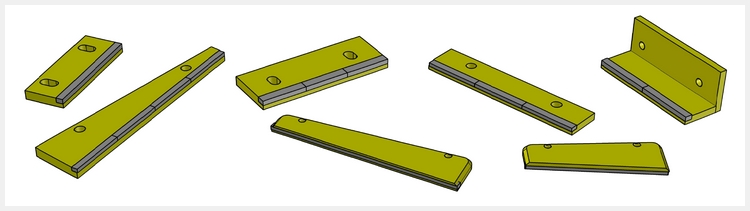

Trail plate

Inside the rotor, a certain amount of aggregate must be stacked to reduce the wear and tear of the body walls and parts, which is called build-up.

The part that determines the shape or size of the build-up is the trail plate.

It is usually made by attaching tungsten carbide alloys to one corner of the steel plate.

|

| |

|

|

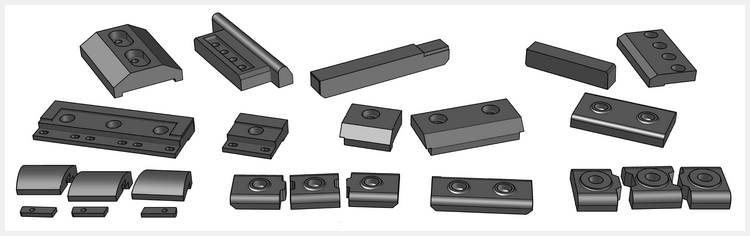

TCWP (Bolt cover, Protection bar, Impact blade)

Liner that protects the side of the rotor body and the rotor tip assembly bolts, and sometimes serves to strike and crush aggregates depending on the model.

It is generally made of high-chrome cast steel, and there are also products with tungsten carbide alloy plates attached to the abrasion area to extend the life.

|

| |

|

|

Upper·Bottom liner (Upper·Lower wear plate)

It is a liner that protects the upper and lower sides in the rotor body. It is usually made of high-chrome cast steel.

There are also products with tungsten carbide alloy plates attached to the abrasion area, and the location and number of tungsten carbide alloy plates can be changed according to the customer's request.

|

| |

|

|

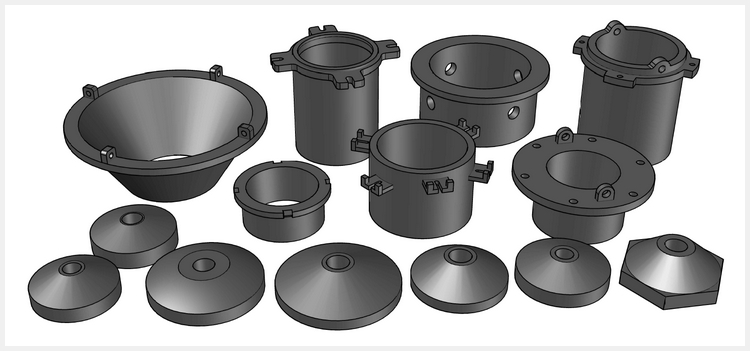

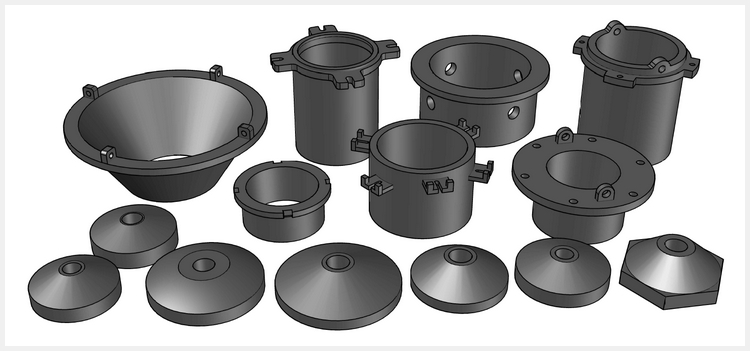

Feed tube / Distributor (Dispersal cone, Feed cone)

Feed tube serves to supply aggregates from hoppers into the rotor, and distributor to distribute aggregates into the rotor.

Feed tubes and distributors are usually made of high-chrome cast steel.

|